Company Profile

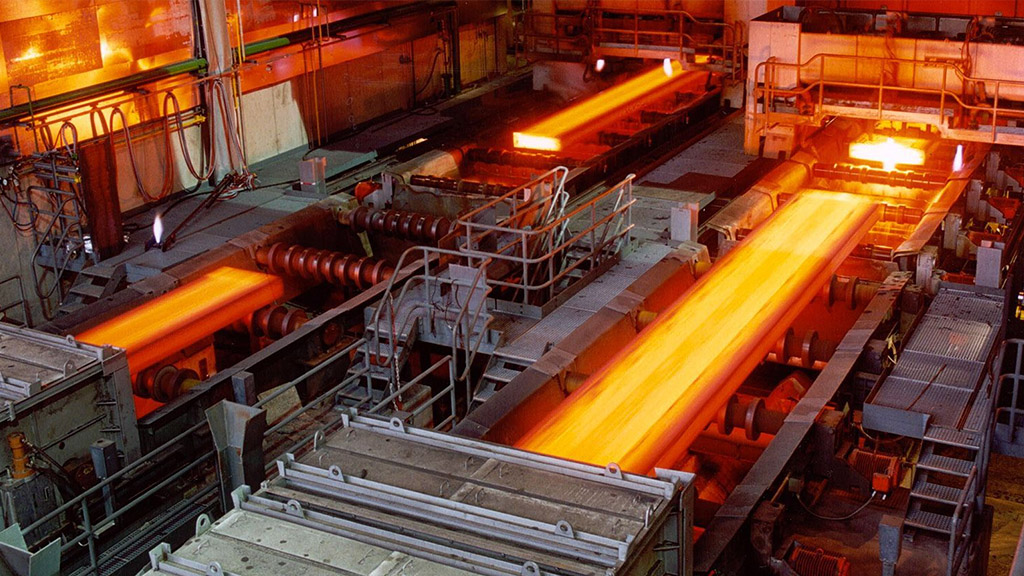

- Producer of steel tubing products

- Internal and external customer base

- 2010 Sales: > $65 million

- Three shift operation

Business Situation

As a consistent, reliable producer operations had little ability to adapt to fluctuations in market or economic conditions. The sales team had developed relationships with customers as a solutions provider but struggle with operations to deliver new solutions.

Solution

Trained and coached the leadership team on strategy deployment assisting each manager to develop annual improvement priorities, identify appropriate goals and assign resources.

Organized key stakeholders to form a steering committee to charter continuous improvement events based on the actions necessary to achieve the future state value stream map.

Trained the sales team on CEM (Customer Experience Management) to better understand and respond to the voice of the customer. The team discovered the customers’ need for smaller order sizes to keep their inventories low with shorter delivery lead times than what the competition could provide.

Benefits

Greatly improving manufacturing flexibility. Sales team increased sales and the solutions based premium over standard pricing.

Change-over times on all production lines: Reduced 50%

Product Line increase: >500%