What is a Productized Solution

For years I have used the term productized solution without defining it. I have been putting it off because I wanted to articulate an alternative without creating another product.

This article is the first in a series which will define productized solutions and at what point they become a problem. The second article will describe an alternative approach and the third will provide a comparison of the two.

Productized solutions are services sold like products with set parameters; standardized, pre-packaged activities used to address familiar challenges. Experts create them by generalizing a successful outcome from one organization to make it applicable to others.

Productize refers to “the process of developing or altering a process, idea, skill, or service to make it marketable for sale to the public.” – Investopedia

Their appeal is in the results they promise, making it easier by providing a prescribed bundle of processes, methods, techniques, and artifacts. They are designed so leaders can get more done. Productized solutions are sold as the ‘easy button.’

The following are what productized solutions look like today:

- Measurement Systems – Zero Based Budgeting, Balanced Scorecard

- Techniques – Problem-solving (A3, 8-Step, 4-D, 5-whys), standard work, 5S, Catch ball, Constructive Feedback

- Methods – DMAIC, Hoshin Kanri, Kanban, Continuous Improvement, TPM, Lean, Six-Sigma, Theory of Constraints, Agile, Business Model Canvas

- Processes – Kanban, Value Stream Mapping, How-To Books, Mail-Merge

- Software Applications – On-line interior design, GenAI, Field service software for contractors

- Training – Management (Zig Ziglar, Blanchard), Masterclass, Udemy, Skillsoft

- Systems – Toyota Production System, Danaher Business System, Wiremold Business System, HubSpot, ISO, ERP

As you can see, not all productized solutions are bad. Problems begin when they start replacing desired behaviors or teach unneeded knowledge, skills, and abilities.

When Productized Solutions Go Bad

Productized solutions often violate reasonable scale, scope, and context. Here are the major ways they go bad:

- Replace purpose or strategic choices – Getting in the way of creating more customers and achieving a competitive advantage.

- Become too large, using up precious time and resources – Pushing the solution to every part of the business when there is no return on investment.

- Go beyond their abilities – When those pushing it assume other capabilities to try and make it relevant.

- Are too complex to manage – Confusion increases the chances of underperformance, excess costs, unexpected results, abandonment, and/or unsustainability.

- Reprioritize activities away from innovation or operations – Creates motion but harms the overall business performance. Costs and time savings at the process or department level do not translate to company or customer improvement.

- Are used out of context – Continually standardizing best practices and driving down inefficiencies when innovation is needed. Used as a management system tempting leadership to delegate their accountability.

Leaders choose or let their staff use productized solutions so they can focus on the right things and do them well[1]. Those in charge assume the solution will deliver as promised. However, productized solutions often fail.

According to Paul Gibbons initiatives like Lean, Six-Sigma, and Business Process Engineering, at best have a success rate of 39%. Culture change succeeds only 19% of the time and business expansion 20%[2]. Culture change fails because it assumes there is something wrong or lacking with employees.

There are business cases as to why expansion is highly unsuccessful. Not understanding the target market and leadership not changing the business model are the most often cited[3].

When functions and tools become a religion in an organization instead of a tool, you will lose the real perspective. – CEO of a Multi-National Enterprise

An Example

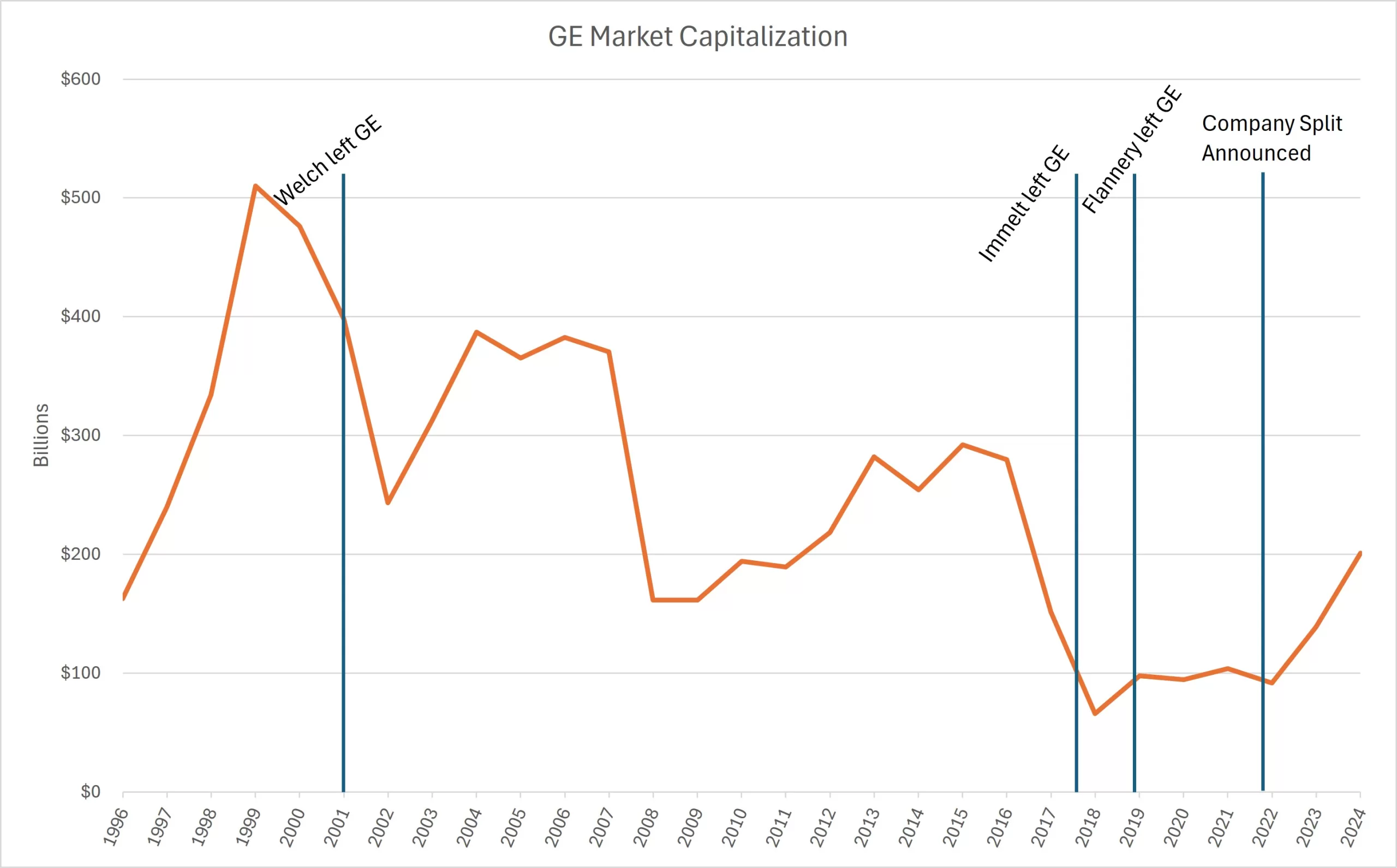

GE is a fitting example of two notable productized solutions used out of context. The period at GE when Welch took over as CEO to the present day is one that shows the long-term effects of the over use of productized solutions. Six-sigma and Lean drove costs and variation out of the business but what GE needed most was innovation and strategic choices.

Product innovation and a more robust resources view of the enterprise to put a finer point on it. Decade after decade GE leadership did what I call “Beating A Dead Horse.” Driving costs out of the business kept the P/E ratio consistent but the company valuation saw a steady decline. Figure 1 shows the continual slide of market capitalization.

Welch had no real strategy so used productized solutions instead. His transactional view of business required the buying and selling of business units as the means to profit and growth. He stated that each division needed to be #1 or #2 in their market. That is not a strategy, it is a goal. To be at the top of your industry and staying there requires innovation. Cost-cutting to success only works for the lowest priced provider.

Today, GE is now three separate entities[4]. Each one with a fraction of the market capitalization and revenue pre-Welch. One could argue that the decline happened after Welch left but culture changes and moving the focus away from GE’s famed innovation set the stage. The foundation was destabilized. Immelt did not seem to strike a balance between reliability and validation of new products. Culp has been touting Lean ever since he took over. Only time will tell if the same dead horse will finally cross the finish line.

Often the losses due to productized solutions are not directly tied to the program itself. The losses come in missed opportunities that your competition did not pass on. It can also allow an industry disruptor to take market share away. Closer scrutiny shows that most companies within an industry can create similar disruptions.

The Price You Pay

Cost overruns are one of six types of failure (there are also underperformance, unexpected results, abandonment, and unsustainability). The losses for all change initiatives including those like IT, put losses from productized solutions in the hundreds of millions of dollars; actual and opportunity costs.

In one study, one in six IT change projects had a cost overrun of 200% on average — resulting in millions of dollars lost.[5]

Sounds counter intuitive but available success stories do not link to productized solutions to the overall effect of revenue or profit. On a larger scale, if one were to look at US productivity and when Lean took hold, you will find no shift, bump, or even an upward trend. Same goes for any of the productized solutions.

What is Fundamentally Wrong with Productized Solutions

The productized solutions I often write about are Lean, Six Sigma, Theory of Constraints, and Business Process Re-engineering (BPR). They aim to offer a quick path to efficiency and effectiveness by providing structured processes and templates that other companies can follow.

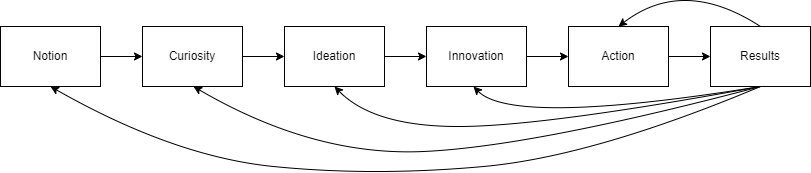

Unfortunately, when productizing, the details of how they became a solution in the first place are scrubbed away. The first part of the Notion to Results cycle (see Figure 2) is cut-off because it is too specific in nature to package for widespread use. Without innovation, a non-productive loop is formed between action and results.

Specific Problems

Productized solutions do not enable employees to sense something different and be curious of what could be next. Even ideation is forsaken because the productized solution tells you what to do. Below are three key problems with productized solutions:

- One-Size-Fits-All Approach

- They force organizations to change to fit the solution rather than adapting solutions to fit the organization.

- They ignore the unique context, culture, and capabilities of individual organizations.

- They often bypass understanding the actual root causes of problems.

- Do not help with developing strategic choices.

- Unable to solve supply chain opportunities like buy versus make.

- Limit Innovation

- Productized solutions can trap leaders into over-refining the current way of doing things rather than exploration of new ways to delight customers.

- They prevent organizations from developing their own best practices. Ones that balance product/service innovation with reliability.

- They can stifle creative problem-solving by giving pre-packaged answers.

- Failure in Practice

- According to studies, programs or methods like Lean, Six-Sigma, and Business Process Engineering have a success rate less than 40%.

- They are used as a way in to an organization. Once inside short wins are used to expand the scope and lengthen the time, for the consultant.

- Constant reliance on the consultant for the next steps or phase.

- They take the focus away from leadership.

- Consultants do them for you instead of by you and your team, so the development of how to turn a notion into results does not happen.

- A good deal of time is spent on learning new words and behaviors not natural to the culture.

- They are designed to make it easier for the consultant and facilitator.

- Training not appropriate for adult learners.

- Confuses activity with progress.

Popular cases of companies that have used Productized Solutions

I have chosen the following companies to highlight the four main reasons productized solutions remain popular. They are ‘Beating A Dead Horse’ (GE), ‘The Cover Story’ (Wiremold), ‘Working Capital Recovery’ (DPS Group), and ‘The Power Grab’.

- GE

- Since Welch took over as CEO, the company has cycled through Six-Sigma and Lean for decades.

- Once an example of the benefits of the company as a portfolio is now pieces of its former self. Delisted from the Dow and now broken up into three separate entities.

- Instead of pursuing innovation, the insistence of wringing out every bit of inefficiency and ineffectiveness has driven it almost out of existence.

- Persistence over so much time gives the illusion that it is working. “Perhaps GE would not exist if it were not for Lean or 6s.”

- Wiremold (What Drives Business Success?)

- To me this is an example where Lean was a cover story

- Byrne used fundamental business tactics like significantly reducing headcount, buying new processes and product designs, and enforcing accountability.

- Pepper Snapple Group (DPS Group) (Lean Did Nothing to Change the Trajectory of the Company)

- My research has revealed that Lean had nothing to do with its success.

- I believe the true story here is the power of a product and brand that competitors could not challenge.

- Also, a case where at least three initiatives obscured the effects that any of them might have had: Zero-Based Budgeting, Lean, and getting the brand in front of the customer[6].

- The Power Grab

- Here the adoption of a productized solution is to fill a perceived void in leadership. It may or may not be to fix something wrong with the business.

- An executive uses a productized solution to cross functional lines so they can do what the leadership team in their eyes has failed to do.

- This often gets traction because doing something is better than doing nothing. People naturally step up when a void in leadership is noticeable. They also cannot outright assume the responsibilities of another department or function.

Is Your Culture Distracted

How do your employees solve problems? Are they addressing the situations most important to your customers and the company? Does everyone recognize the right scale and scope of the solution, given the context in which they are developed?

In the next article of my series, I will describe a better way to drive strategy, value creation, and improvement. It is not another product but a way to develop a pattern of thought natural to your culture and capabilities. It is then taking that way of thinking to develop best practices by creating a cycle from notion to result. As a reference, I will use my mental construct developed over thirty years working in business.

[1] A nod to Peter Drucker. Productized solutions are meant to be one of the things to do the right thing well. Not to be a replacement for the right thing.

[2] ‘The Science of Organizational Change: “How Leaders Set Strategy, Change Behavior, and Create an Agile Culture;” Paul Gibbons.

[3] https://www.mediabeacon.com/en/blog/case-study-social-understanding

[4] https://www.investopedia.com/insights/rise-and-fall-ge/

[6] https://www.wsj.com/articles/how-dr-pepper-cuts-costs-and-keeps-cutting-1456110339