Alternative Techniques to a Lean-or-Bust Approach

In 2008, I gained an appreciation of the difference between productized solutions and a personalized approach. This realization happened while attending a Lean summit of all things. I observed most participants were staff-level employees who wanted to know “How do I convince my boss to let me use Lean?”

I wondered what the people who intentionally did not go to the summit were thinking — what did they know that I didn’t? From that point forward, I set out on a self-discovery for a better way to improve business performance and customer satisfaction.

Productized solutions are not “bad” if people understand what they are and their limitations. The best and perhaps the only use for them is to open people’s minds to new ways. The first book on Lean was as far as Lean should have gone.

Once awareness of a new way has been introduced, further explanations or details stifle innovation. Have you ever read or heard something that starts your mind racing with all the possibilities? Did more listening or reading give you the feeling that the wind was being taken out of your sails?

Context and freedom to explore are innovation’s best friends

Conversely, the enemies of innovation are incessant details about one thing or how someone else used it. Context is important because it is a high-level boundary to the possibilities; it provides focus but gives you room to explore. Imagination and sharing, not more explanation, are the secret ingredients to creativity.

My favorite method for developing personalized frameworks is Feynman’s technique: a methodology that brings existing mental models into consciousness and looks for ways to improve them.

Relying on our outdated mental models or heuristics prevents us from finding better solutions. When confronted with a challenge, dilemma, or problem, write down everything you know about it. Analyze what you’re unsure about and look for holes in what you believe to be true. Then, get others’ perspectives, knowledge, and experiences, and research literature on the subject.

In most cases, new facts broaden your understanding or can even change existing beliefs. What does the new model look like when putting all the pieces together (new and old)? Because you started with a relevant issue, the best thing to do is try your new approach in the real-world. Including others is key — not only can they expand your understanding, but they can also learn from the results.

I’ve become so comfortable with this approach that I use it with clients. Instead of asking them to accept every one of my perspectives, I take what they know and show them how to improve upon their understanding.

How do you use Feynman’s technique?

You can break Feynman’s technique down into five steps as follows:

- Articulate exactly what you want to know or learn

- Write down and self- evaluate your current understanding

- Research new knowledge

- Record new knowledge and spell out new insights

- Synthesize an evolved understanding similar to step 2)

Using this technique has helped in breaking down productized solutions to where I can examine the underlying principles. Understanding the building blocks of a solution may introduce you to new concepts, but more importantly, it adds to your repertoire. Starting with the fundamentals is the first step in developing a personalized framework for sustainable change.

What role does leadership play?

People will try to close performance gaps by adopting a productized solution without identifying the root causes. Rarely does this work. It’s not just because of a misunderstanding of the cause(s), but more substantially because the solution is used as a substitute for leadership. The thinking is that getting others to implement a mandated solution is the same thing as effective delegation.

It’s a leader’s responsibility to provide clear expectations, remove barriers, and supply resources. Without leadership and a focus on the fundamentals, attempts at change fail. What’s worse is future change initiatives will be labeled the “Flavor of the Month.” People won’t trust their leaders to get it right.

Where to begin? Start with the fundamentals

The justification for using any approach should be based on top-level key performance indicators. Those should link to every area of the business.

Customers and employees need to understand the cause and effect that is happening. Only when you get to the root cause of your performance gaps can you answer with the appropriate solution(s). How you measure your business is the beginning of knowing what and how you should change.

Change starts with the fundamentals, not sweeping change. Once strategic choices have been made, building the how requires context and innovation. The context I use for business includes a value proposition, measured performance, and the work environment.

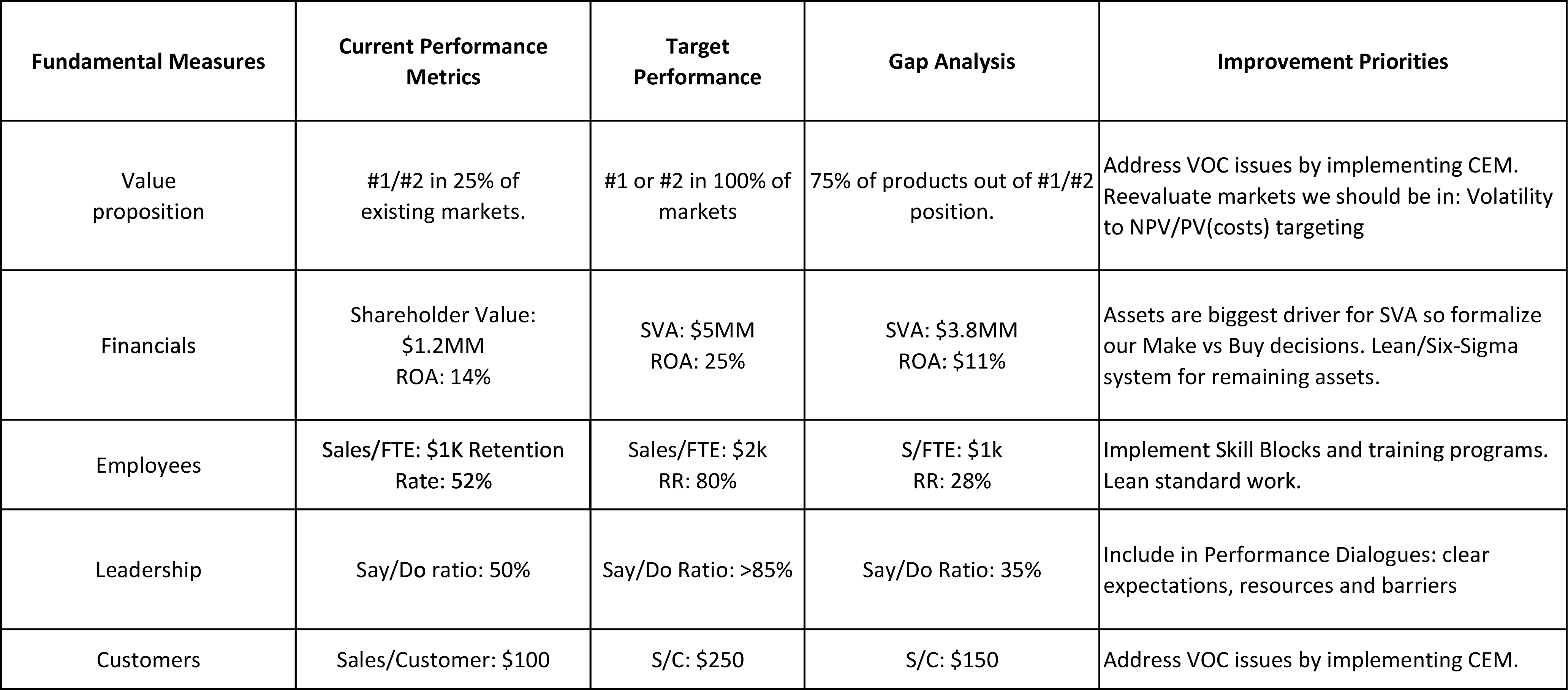

Important ingredients include leadership, capabilities, and customer comprehension. I like to pivot from measured performance because it’s measured, and any effort to improve must affect results. Table 1 below provides an example of a few fundamental measures and how they point to gaps in performance.

Key: CEM – Customer Experience Management; VOC – Voice of the Customer; SVA – Shareholder Value; ROA – Return on Assets: Net Profit before taxes / Total Assets; FTE – Full Time Equivalent; Say/Do Ratio – Compares performance plan to actualBefore deciding on how to make changes, step back and confirm or determine what drives your business performance and the strategic choices made. Ensure leadership, functional, and operational levels understand their part in realizing the choices they make and have the necessary capabilities.

Measures at every level should align with the ultimate markers of success: your customers’ behaviors and company objectives. The dissemination of strategic choices and marshaling of capabilities drive the necessary changes to your business, not productized solutions.

For more information on productized solutions see my article: Lean… Just Another Productized Solution